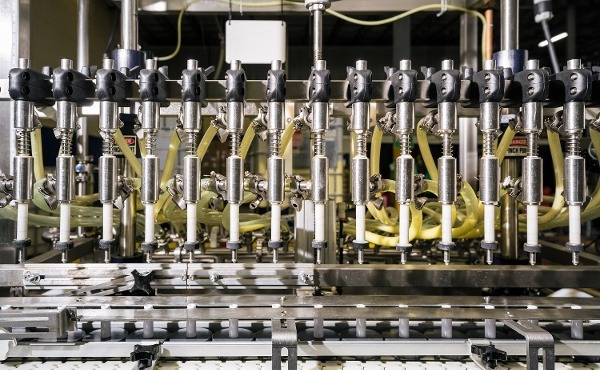

Verst provides one-source contract packaging, shrink sleeve labeling and contract decorating for many of the most recognized brands in the world. With industry leading capacity, we specialize in large volume projects, 100,000 units and greater. Our team has decades of experience and the technical acumen to deliver efficiency, savings and speed to market for clients.

By outsourcing to Verst, the industry’s largest shrink sleeve labeling expert, clients avoid costly capital outlay for tooling, inventory and warehousing. Whether for a global brand or an entrepreneurial operation, Verst can design a cost-effective and reliable solution that fits unique needs precisely.

Wrap it up with style. Our shrink bundle wrap technology is a game-changer for your personalized packaging needs. Our state-of-the-art equipment can handle multiple flavors and product types. Brand your bundle with flexibility and reliability.

At Verst, we’re known for getting products to market faster. That’s because we streamline the process. Our fully automatic systems palletizers handle bottles and cans. We can do customized configurations to meet your needs.

Not only can we automatically load items on to pallets — we can also do the reverse with a pallet jack. Our depalletizers unload pallets, and our repalletizer transfers goods from one pallet to another. We make it seamless.

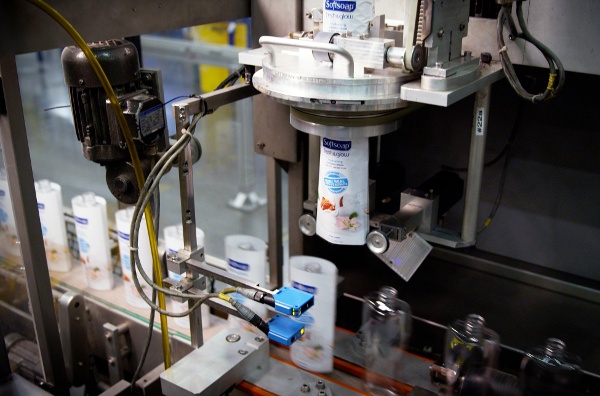

Pre-blended liquids filling

We package products together as a single package to increase sales and reduce picking, packing times, and errors. This is great for special promotions, introducing new products, or cross-selling.

No matter how unusual or complex your packaging needs are, Verst is ready and willing to design a solution that meets your unique requirements.

As the largest shrink sleeve labeling operation in the industry and more than 30 years of experience on a vast array of products, our team of technical experts bring unmatched knowledge to projects of all kinds.

We built our business on quality. That’s why our quality standards are among the highest in the industry—and we can prove it. Our scrap rate is less than 1%.

With more than 400,000 square feet of production and warehouse space, Verst offers everything clients need to be up-and-running right away, get to market faster, and minimize the cost of empty bottle shipping.

Extensive Experience in Industries Like

Personal & Household

Wine & Spirits

Special Effects Printing

Food & Beverage

The Verst team is well versed in all the technical aspects of product packaging and will guide you through a project of any size and scope. Will Schretzman, VP of Packaging, has more than 30 years of industry experience and is a sought after packaging authority. When you source with Verst, your project is in capable hands.

Director, New Business Development

Director of Packaging Operations

Get started on the road to better supply chain performance today by contacting us

Resources

Connect