At Verst, our team has a proven process for designing effective solutions for omnichannel and B2C fulfillment, warehousing, packaging, and transportation. Our experienced solutions team works closely with our customers to understand every aspect of their requirements in order to design and implement optimal solutions.

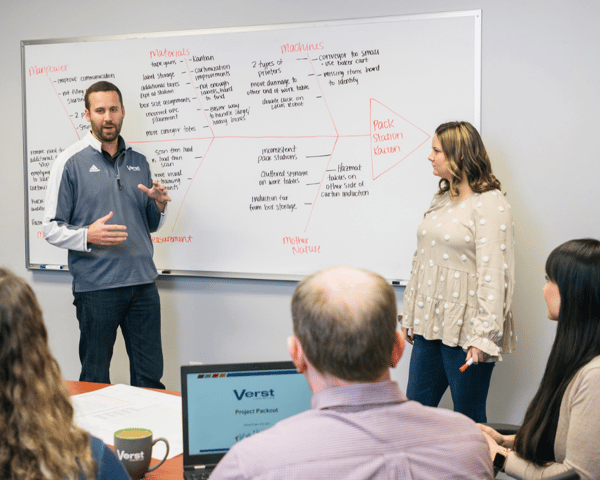

We don’t rest on our laurels once a successful solution is up and running. We apply LEAN Six Sigma concepts to identify ongoing opportunities for continuous improvement.

Our team uses the latest productivity and design software, proprietary pricing process, industry best practices, and our vast expertise to develop a solution to meet customer objectives.

With Verst, customers gain the benefit of our operational expertise gleaned from decades of solution design experience, best-in-class standards in every solution we deploy, state-of-the-art processes and industry leading technology. What’s more, we have an in-depth understanding of the labor market and its challenges, so we are always evaluating where we can use automation as a strategy to ensure new efficiencies, increase shipping accuracy and more.

Every solution design starts with our team conducting a thorough analysis of challenges, objectives, and requirements. Once we understand every aspect of the business, we begin the design process, which includes:

Material handling equipment and automation

WMS selection and project implementation

Facility layout and design

Work measurement to determine staffing requirements

Operating Budgets

At Verst Logistics, excellence isn't just a goal; it's a way of life. Through benchmarking, the implementation of key performance indicators (KPIs), and the utilization of an advanced Warehouse Management System(WMS) technology, we continuously measure, monitor, and improve our processes to streamline operations, eliminate inefficiencies, and provide unparalleled service to our customers. Our commitment to continuous improvement, driven by the power of Lean methodology, ensures that we consistently exceed industry standards and deliver exceptional results.

At Verst, we constantly benchmark best practices across our 26 facilities within the network. Continuous improvement is a grassroots up process—and all levels of the...

Read MoreAt Verst, we constantly benchmark best practices across our 26 facilities within the network. Continuous improvement is a grassroots up process—and all levels of the Verst organization look for new opportunities to optimize our customer operations. We set annual cost savings goals and track key performance indicators (KPIs) to measure performance and progress.

Read Less%20(2000%20%C3%97%202000%20px)%20(5).png?width=600&name=100%20(1200%20%C3%97%202000%20px)%20(2000%20%C3%97%202000%20px)%20(5).png)

Our Warehouse Management System (WMS) is unique—a true multi-tenant, multi-company, multi-facility, multi-lingual enterprise WMS powered by Korber. Designed for...

Read MoreOur Warehouse Management System (WMS) is unique—a true multi-tenant, multi-company, multi-facility, multi-lingual enterprise WMS powered by Korber. Designed for 3PL logistics and omnichannel fulfillment, it offers a modular approach with virtually unlimited configurability for warehousing.

Verst provides the highest level of customer service at the lowest possible cost.

Verst reduces labor costs and tracks the efficiency of each workflow and employee.

Verst provides repeatable, predictable service with 100% vendor compliance.

Verst operations utilize a feature-rich, world-class warehouse management platform to track items accurately, at any point in time.

Read Less

Our skilled team and innovative approaches guarantee top-quality projects through internal audits, cutting-edge methodologies, and optimized processes. By...

Read MoreOur skilled team and innovative approaches guarantee top-quality projects through internal audits, cutting-edge methodologies, and optimized processes. By collaborating and fostering a culture of innovation, our exceptional team consistently exceeds expectations.

Partner with Verst and experience our passion for quality, innovation, and customer satisfaction. As a result, our customers achieve increased cost-effectiveness and efficiency.

We employ a comprehensive range of tools, including Basic and Advanced LEAN tools, Just Do It (JDI), and DMAIC or DMADV Six Sigma, to drive continuous improvement and deliver superior results.

At Verst Logistics, our unwavering commitment to excellence drives us to continually enhance our services and exceed our customers' expectations. Embracing the transformative power of Lean, we are dedicated to optimizing our processes, eliminating inefficiencies, and delivering an unparalleled experience to our valued clients.

We are fully committed to achieving ongoing improvement across these four essential areas:

At Verst Logistics, our unwavering commitment to excellence drives us to continually enhance our services and exceed our customers' expectations. Embracing the transformative power of Lean, we are dedicated to optimizing our processes, eliminating inefficiencies, and delivering an unparalleled experience to our valued clients.

We are fully committed to achieving ongoing improvement across these four essential areas:

Get started on the road to better supply chain performance today by contacting us

Resources

Connect